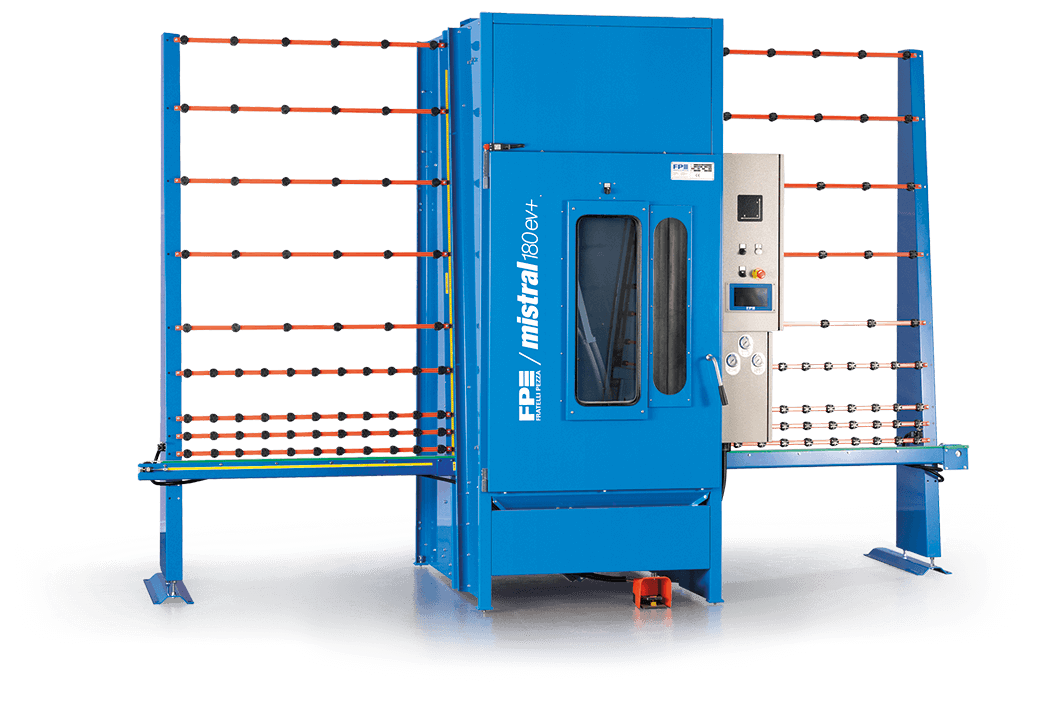

The automatic sandblasters of the MISTRAL series are vailable in 3 models: MISTRAL 120EV+, 180EV+ and 260EV +(max. working height 1200, 1800 and 2600 mm). Sturdy and compact machines with small overall dimensions, easy to use by any operator, they are characterized by high productivity and low consumption of electricity and compressed air, and provide a wide range of processing options. It is possible to operate both automatically and manually and the maximum working height can be doubled thanks to the fact that the cabin is open topped. Mistral EV+ is the most used sandblaster by LED mirrors manufacturers. They take advantage of the custom-made software (in particular of the zonal blasting feature) which allows to effectively remove the silvering and optimize the process. Moreover, all models are equipped with “MirrorProtection”, a revolutionary system that limits the accumulation of static electricity within the cabin avoiding sparks, a phenomenon that often occurs during sandblasting on mirrors. The shading effect on glass, in particular for shower boxes, has become a trend in bathroom furniture design. Mistral EV+ allows to carry out different kinds of shading effect, giving a wide range of decoration options to interior designers. The sandblasters are equipped with a high efficiency filtration system with automatic recovery and recycling of the abrasive material and separation of waste dust. The rubber gaskets ensure airtight seal, preventing the dust from escaping into the surrounding environment. All versions are compliant with the requirements of Industry 4.0. Interconnection, digitalization of the production process and constant monitoring of performance are key factors for the competitive development of glass companies. The blasting cabins are equipped with a touch screen control panel. Programming is extremely easy and intuitive. The software allows to the operator to manage an unlimited number of working programs, copy, rename, delete and backup them. It is also possible to set up to 50 different blasting areas on the same glass plate which are shown on the display through a graphic simulation. The “Pause&Check” feature allows to stop the working program, even a very complex one, and restart it exactly from where it was stopped, without being obliged to restart it from the beginning. Predictive maintenance alerts notify the operator when it is necessary to check the wearing status of components or spare parts in order to prevent any problems or machine downtime.

It is now available “MistralApp” the new web application that allows the Mistral EV+ series sandblasters to be programmed remotely by PC or tablet. With MistralApp, glass companies will be able to optimize programming and processing times, significantly reducing production costs and consumption.

Here are the main advantages:

• create programs remotely while the machine is running, without interrupting the process;

• view a preview of the glass to be processed and of the sandblasting areas in order to facilitate programming and limit consumption;

• name, modify and copy programs adapting the same process to different glass formats;

• make a backup of the programs directly on the PC;

• share the programs with Fratelli Pezza to identify the best settings for each process.